Future-Proof Printing with HSAJET® Premium Printers

Probind Mohn Media Binding GmbH, based in Harsewinkel, Germany, has taken its production to the next level. They have chosen to expand their production lines with more printers from HSA Systems A/S. In total, the company is now equipping eight of its production lines with HSAJET® Premium printing systems.

The decision was driven by the need for reliable, flexible, and low-maintenance solutions that could handle high volumes while adapting to diverse production requirements.

“The simple design and low maintenance requirements were particularly convincing both at the first decision for the system and later expansion,” explains Stephan Spoida from the Addressing Team. This combination of reliability and efficiency ensures the systems deliver smooth operation with minimal disruption to daily workflows.

Holger Schwark, Account Manager at HSA Systems GmbH (left) and Stephan Spoida, Addressing Team at Probind Mohn Media Binding GmbH (right) looking at one of the Premium installations

Individually adapted printing solution with remarkable flexibility

A key factor in the project’s success was the InkDraw software. “The software was individually adapted to our specific requirements. In particular, the extended PDF functions ensure seamless integration into existing processes,” says Holger Schwark, Account Manager at HSA Systems A/S.

The HSAJET® Premium systems also proved their versatility. Supporting a wide range of substrates and ink types, they ensure dependable results even with challenging materials. “Even with demanding materials, we can rely on consistent results,” confirms Spoida.

Reliable performance across diverse applications with minimal downtime

Probind Mohn Media has also experienced a significant increase in performance due to the Premium solution. “Thanks to the HSAJET® Premium printing systems, we were able to significantly reduce downtime. Even at speeds of over 20,000 copies per hour, the system runs reliably and without disruption,” highlights Ralf Hagenlüke, Head of Process Engineering.

Holger Schwark (left), Ralf Hagenlüke, Head of Process Engineering at Probind Mohn Media Binding GmbH (middle), and Stephan Spoida (right)

A Future-Proof Investment

Flexibility across applications further strengthens the company’s processes. “The new solution enables uniform operation of various applications such as carton or cut-sheet printing. This significantly increases the flexibility of our processes,” adds Michael Blanke, Production Manager.

From both a technical and economic standpoint, the investment has proven to be future-proof. Increased productivity, reliable performance, and versatile functionality made the decision clear. Summing up the collaboration, Blanke notes: “The cooperation with HSA Systems was excellent in all project phases – solution-oriented, fast, and reliable. Even with tight production schedules, we always receive quick and competent support.”

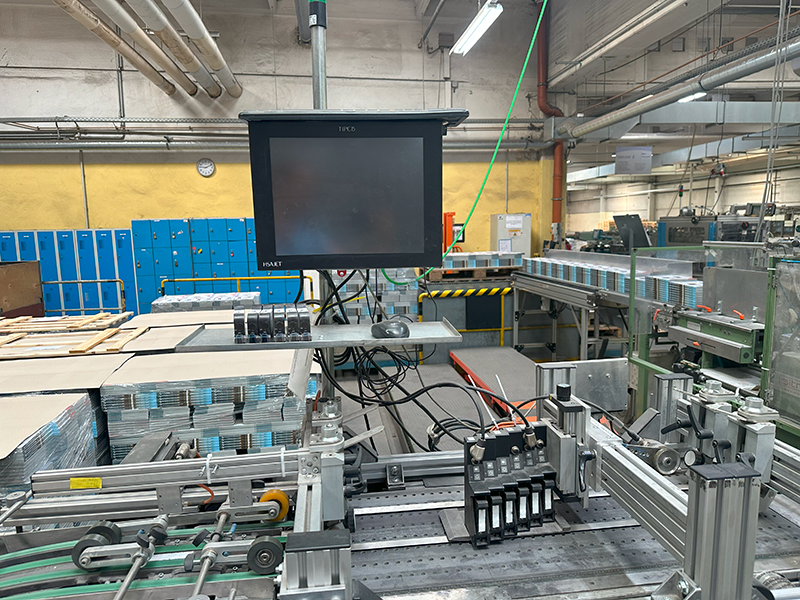

HSAJET® TIPC Premium 6-pen printhead

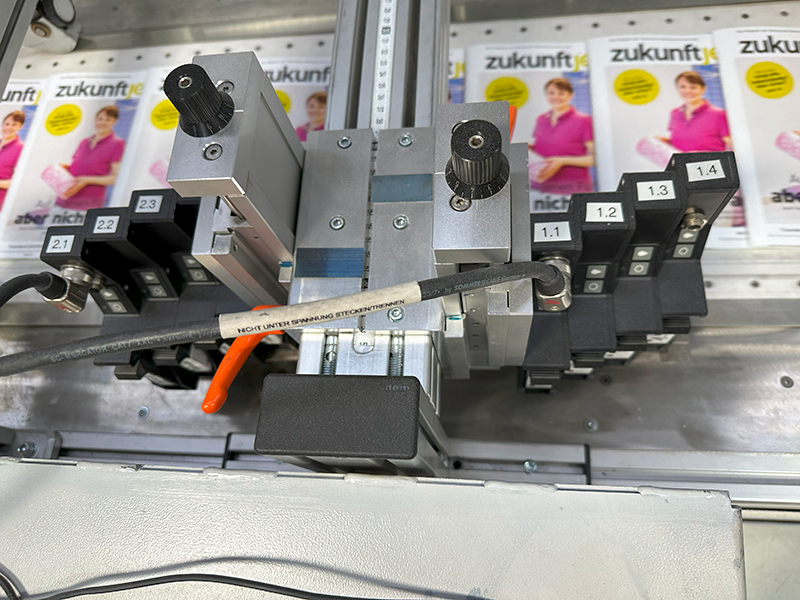

HSAJET® TIPC Premium 2 x 4-pen printhead